Aircraft Sheet Metal Repairs - Afast Aero can provide highly skilled, fully equipped construction teams when an AOG situation arises or when our clients simply don't have the resources to cover an unexpected workload. Our dedicated quality workforce can travel anywhere in the world at short notice. They are innovative individuals with the excellent work ethic and skills required to deliver real financial solutions to our clients.

Each team member has over 20 years of current industry experience covering all major/minor repairs and alterations. All of them were chosen to represent our team, having already worked with our management on many projects over the years.

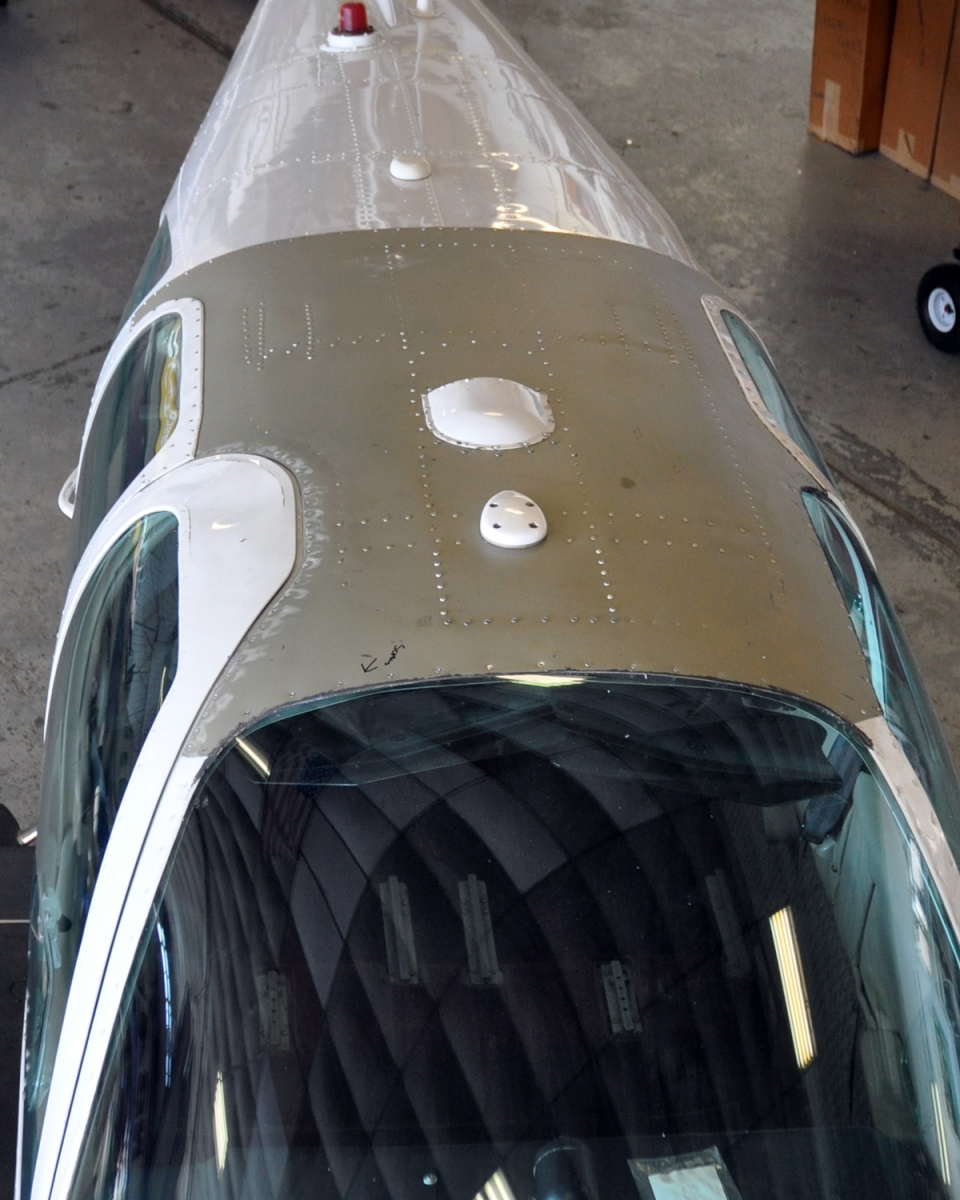

Aircraft Sheet Metal Repairs

Our sheet metal workers are also qualified and equipped to carry out their structural works from post to entry and re-installation and reduce the workload of clients.

Component Repair & Overhaul

Our teams can work on any type of aircraft, but on request we can provide CRS for most commercial types working with our Part 145 partners covering all aspects of operations, planning, logistics, manpower, NDT. , garage, etc.

Most of our customers want speed, quality and value for money. Repeat business shows us that we can and often do overcome their challenges. When repairing a damaged part or component, refer to the appropriate section of the manufacturer's SRM for the aircraft. In general, a similar repair is described and the material, types of rivets and spacing of the spoon, methods and procedures to be used are given. Any additional knowledge required for repair is also detailed. If the required information is not found in the SRM, try to find a similar repair or assembly installed by the aircraft manufacturer.

Due to the rapid rate of corrosion on metal parts, periodic and frequent inspections are required to maintain the fins in airworthy condition, especially when the aircraft is operated in salt water. Inspection of floats and hulls includes checking for damage caused by corrosion, collisions with other objects, hard landings, and other conditions that may cause damage.

Tape floats must be repaired using approved methods; However, joints between sections of sheet metal must be waterproofed with a suitable fabric and sealant mixture. A reconditioned float should be tested by filling it with water and allowing it to stand for at least 24 hours. [Figure 1]

Lee Aerospace Aerostructures

Some controls on small general aviation aircraft have beading on the skin panels. The beads give some stiffness to the thin skin plates. Beads for repair patches are created with a rotating former or a press brake. [Figure 2]

Damage to the metal aircraft skin beyond repairable limits will require the entire panel to be replaced. [Figure 3] Even if there have already been many repairs in a particular section or area, it is necessary to replace the panel.

In aircraft construction, a panel is any sheet of metal covering. A panel section is the portion of the panel between the adjacent stringers and baffles. If a piece of skin is damaged so that a standard skin repair cannot be installed, a special type of repair is required. Whether the damage is on the outside of the member, inside the member, or on the edge of the panel, it requires a specific type of repair.

If the outside of the member, after cutting, contains 81⁄2 scoop diameter or more of material, add the patch to the manufacturer's row of rivets and add an additional row to the inside of the member.

Basic Principles Of Aircraft Sheet Metal Repair

For damage to the member, after cutting, if the member contains less than 81⁄2 manufacturer's scoop diameter of material, use a patch extending over the member and an additional row outside the member.

For damage where the panel edges extend to the edge of the panel, use only one row along the edge of the panel unless the manufacturer uses more than one row. The procedure for repairing the other edges of the damage follows the methods described earlier.

The procedures for all three types of panel repairs are similar. Cut off the damaged part up to the allowance mentioned in the previous points. To reduce stress on cut corners, round them to at least a ½-inch radius. Lay a row of new studs with a horizontal pitch of about five board diameters and drive them with the manufacturer's installers. 21⁄2 in diameter, cut a patch plate from the original or next thick material of the same thickness, leaving a distance of one edge. At the corners, draw arcs with a radius equal to the edge distance.

Hold the edges of the plate at a 45° angle and shape it to match the shape of the original structure. Turn the edges down slightly so that the edges are close to each other. Place the patch plate in place, drill a drill hole, and secure the plate with a temporary fastener. Using a hole finder, locate the second hole, drill it, and insert the second fastener. Then, from the back and through the original holes, locate and drill the remaining holes. Remove the blades from the screw holes and apply corrosion protection material to the contact surfaces before patching.

Economy Of Effort

Lightning Hole Repair As discussed earlier, lightning holes are cut in rib sections, fuselage frames, and other structural components to reduce component weight. The holes are ridged to strengthen the mesh. Cracks may develop around flanged lightning holes and these cracks should be repaired with a repair plate. The damaged area (cracks) should stop drilling or remove the damage. The repair plate is made of the same material and thickness as the damaged part. The spacers are similar in construction and the minimum edge distance is 2 times the diameter, the gap is four to six times the diameter. Figure 4 shows a typical method of repairing lightning holes.

Repairing Pressurized Areas Pressurized aircraft skin is subjected to severe stress during flight. Pressure cycles place loads on the skin, and repairs to these types of structures require more inserts than repairs to non-pressurized skins. [Figure 5]

Stringer Repair The fuselage stringers run from the nose to the tail of the aircraft, and the wing stringers run from the fuselage to the wingtips. Control surface stringers typically extend the length of the control surface. The fuselage, wing or control surface skin is nailed to the stringers.

Strings can be damaged by vibration, corrosion or impact. Because stringers are made in different shapes, repair procedures vary. Repairs may require preformed or extruded repair material, or may require material designed by an airframe technician. Some repairs may require two types of repair materials. When repairing a stringer, first determine the extent of the damage and remove the surrounding corners. [Image 6] Then remove the damaged area with a hacksaw, key saw, drill, or file. In most cases, you will need to use an insert and add angle to fix the stringer. When determining the stringer connection angle during repair, be sure to refer to the appropriate structural repair manual for the location of the repair part. Some stringers are fixed by placing them inside the connecting corner, some are fixed by placing them outside.

Sheet Metal Bending And Forming

Extrusions and fabrications are often used to repair corners and inserts or fillers. If repair corners and fillers are to be made from flat sheet, use brake. For these molded parts, it may be necessary to use a bend path and sight lines when making the layout and bends. To repair bent stringers, make the repair parts to match the original shape.

Figure 7 shows the repair by patching the stringer. This repair is permitted if the damage does not exceed two-thirds of the width of the foot and is no longer than 12 inches. Losses beyond this limit are corrected by one of the following methods.

Figure 8 shows the loss of two-thirds of the width of the foot and correction by insertion after removal of a portion of the stringer. Figure 9 shows repair by insertion if the damage affects only one stringer and is more than 12 inches long. Figure 10 shows repair by insertion when a fault affects more than one stringer.

Compartments are oval-shaped members of the fuselage that shape and maintain the shape of the structure. The chambers or shapes are often referred to as forming rings, body rings, perimeter rings, girdle rings, and similar names. They are designed to carry concentrated compression loads.

California National Guard Makes Historic Gray Eagle Repairs > National Guard > Article View

There are different types. The most common type is a curved channel made of sheet metal with stiffeners added. Others have a sheet web with extruded corners butted together.

Aircraft sheet metal repair, aircraft repairs, aircraft sheet metal fabrication, aircraft sheet metal, aircraft sheet metal fabrication and repairs, aircraft sheet metal worker, aircraft sheet metal tool kit, aircraft instrument repairs, aircraft aluminum sheet, aircraft sheet metal tools, aircraft sheet metal mechanic, aircraft sheet metal jobs

0 Comments